A slicer, in other words, known as a slicing software, is computer software that is mainly used in the process of 3D printing. The slicer, like the creality slicer, is used to convert the 3D model to instructions that the printer can translate. In technical terms, the slicing software turns 3D models into G-Code (a language that the printer can understand). Once the object design has been fed into the printer using the modeling software, the slicer begins by dividing the object design into a stack of flat layers. After that, it also begins converting the layers into linear movements to be followed by the 3D printer.

Features of 3D slicing software

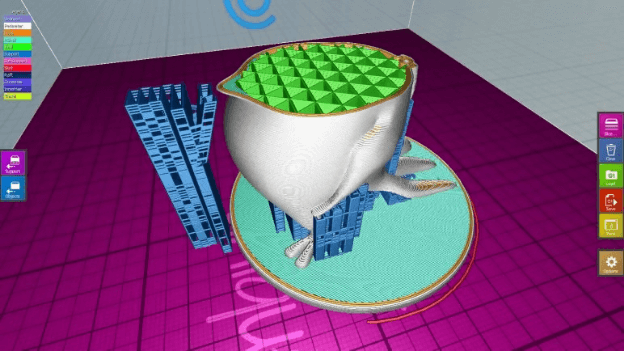

Infill- this is the element of the slicer that allows it to automatically translate solid volumes into hollow ones that can be filled partially by internal structures to provide robustness. The amount of internal structures is referred to as the infill density, and the slicer provides it.

Supports- the role of the support element is to grip the objects so that it can easily be detached from the slicer once the process of production is complete. It is used during the production of intricate designs like roofs that are suspended (floating) from the base.

Skirt- This is a single band that the slicer automatically adds at the base of the object without touching it to avoid issues like adherence to the bed.

Brim- These are several lines of filaments that automatically form at the base of the object.

Rafts- These are several layers of material that form a detachable base over which the object is printed.

Features of an excellent 3D printer

Preview- an excellent 3D slicer gives you an accurate estimate of the time and the material to be utilized during the printing process. This gives you the chance to plan for the process hence making the workflow flowless. Be keen to make sure that the estimates do not differ from reality.

Viewer compatibility- An excellent 3D slicing software offers the possibility to turn and zoom to any point of the 3D model without any issues. The process should also be fast.

Cost- there is some free slicing software on the internet to choose from. However, the more complex ones have to be purchased. It is wise to get purchasable slicing software as it is more efficient. However, choose a price that suits your budget and consider the features before determining the one to choose.

Usability- Using a 3D slicing software for the first time may not be as easy as perceived. There are several settings to master and options to choose from. When looking into the usability of the software, such aspects to consider are the storage of files, workflow, ease of redoing and undoing an action, subjectivity, and beginner settings.

Bottom Line

The quality of the slicing software determines the quality of the end product. The quality, however, has to match the mode operation of the software. For a better experience, you have to learn how to operate the software properly. This is where a guide comes in handy.